Blog Post

Blog

D110 Type III, Prestressed Concrete Tanks Lead the Way

Following years of development, Preload constructed the first wire-wound prestressed concrete tank in 1941, which set the standard for durable, low-maintenance storage tank structures. Then and now, Preload’s designs utilized the basic building materials and concepts of domed concrete structures constructed hundreds of years ago, which continue to provide service today.

Preload combined these time-proven design concepts and materials with advancements in construction methods to produce the modern wire-wound prestressed concrete tank. After 80 years and thousands of prestressed concrete tanks constructed, no other type of storage tank has met the bar set by Preload for the highest reliability coupled with the lowest cost of maintenance.

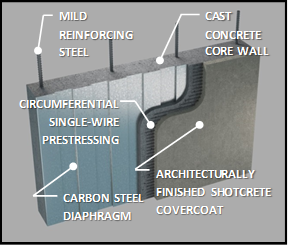

Decades of experience constructing prestressed concrete tanks have led to advancements in the original technology, but the time-proven fundamentals remain. Single-wire prestressing is precisely applied to place the core wall into compression to eliminate cracking, thereby increasing durability and the life of the tank structure. The concrete and shotcrete encased steel shell diaphragm ensures water tightness over the tank’s life. Each of these features set AWWA D110 prestressed concrete tanks apart from other types of prestressed concrete tank structures and assure a low maintenance structure.

Today, the industry benchmark for prestressed concrete tanks is the AWWA D110, Type III tank. AWWA D110, Type III tanks provide an unmatched level of quality assurance, safety and durability in some of the world’s most unforgiving environments. In fact, no other type of prestressed concrete tank has the proven record of success and longevity. The reinforced, precast concrete core wall sets the Type III tank apart from other types of AWWA D110 tanks.

This method of design and construction employs a minimum of four inches of reinforced concrete between the steel shell diaphragm and the liquid contents. The high-quality concrete protects the watertight steel diaphragm, which in turn provides maximum durability and longevity. Preload’s team of the most experienced engineering and construction personnel in the industry have successfully constructed thousands of prestressed concrete tanks of all Types; however, no other AWWA D110 tank Type has met the standard set by the Type III tank.

As communities expand with outward development, infrastructure that was once hidden has become visible to the public. Aesthetically pleasing structures, which match the character of the community and its environment, are in public demand. Preload offers myriad customized architectural options and treatments to assure that the community’s tank will be a source of pride and a landmark for generations. While some tank structures offer a very limited opportunity for the incorporation of architectural treatment, Preload prestressed concrete tanks can be designed and constructed to fit seamlessly into almost any environment. Decorative arches, brick pilasters, stamped precast panels and modern building cladding systems are just a few of the options available to an engineer and owner for architectural enhancement.

For the best in storage tank structures there is a clear front-runner, the AWWA D110, Type III prestressed concrete tank, and Preload leads the way.

Contact Us

Related Blogs

Latest Updates

PRELOAD names Eden Prairie, MN Winner of the 2022 Concrete Decision Award, Top Tank of the Year

2022 produced some fantastic tanks for Preload. What better way to end this event than by announcing the annual Concrete Decision ...

READ MORE2022 Concrete Decision Award Top Tank – Vote now!

PRELOAD Opens Voting for the Concrete Decision Award 2022 Top Tank PRELOAD, the industry leader in prestressed concrete tanks, cel...

READ MOREPRELOAD Names Concrete Decision Award 2016 Top Tank Winner

PRELOAD, LLC, the leader in prestressed concrete tank design and construction, announced the City of Fort Worth’s 5.0 MG Caylor ...

READ MORE