Design & Construction

The PRELOAD Advantage

PRELOAD has maintained a focused vision on designing and constructing the highest-quality and most durable liquid storage tanks for over 90 years. From the first-ever wire-wound, prestressed concrete tank to the advanced tanks of today, PRELOAD’s legacy is built on the design and construction of more than 4,000 tanks worldwide. PRELOAD tanks are designed and constructed to meet or exceed applicable industry requirements as contained in the following:

- American Water Works Association (AWWA) D110, Wire- and Strand-Wound, Circular, Prestressed Concrete Water Tanks.

- American Concrete Institute (ACI) 372R, Design and Construction of Circular Wire- and Strand-Wrapped Prestressed Concrete Structures.

- American Concrete Institute (ACI) 350, Code Requirements for Environmental Engineering Concrete Structures.

- National Fire Protection Authority (NFPA) 22, Standard for Water Tanks for Private Fire Protection.

Singular Responsibility

From detailed tank design through completed construction, PRELOAD provides “singular responsibility” for all our clients. Singular responsibility ensures every project detail is exceptionally managed, including implementing the highest quality standards and processes necessary to provide a virtually maintenance-free liquid storage solution.

Leading Tank Innovation

PROVIDING THE MOST DURABLE, LOW-MAINTENANCE TANK STARTS WITH AN EXPERIENCED, FOCUSED DESIGN TEAM.

Since constructing the world’s first wire-wound prestressed concrete tank in 1941, Preload’s engineers have led the industry in Innovation and Quality. Even after 90 years, our engineers continue to collaborate with owners, consultants, material providers, and field crews to advance the design.

All AWWA D110, Type III Wire-wound Prestressed Concrete Tanks feature Concrete Floor, Precast, Watertight Steel Shell Diaphragm, Concrete Core Wall, Sliding Floor to Wall Base Connection, Circumferential Wall Prestressing and Concrete Roof (as required). These elements combined create the most proven, watertight, durable, efficient, and low-maintenance tank in the world.

World-Leading Design

Learn About The Our World-Leading Design Features

Accessories

After the construction of the tank is complete, accessories are added to complement the tank structure based on specific project requirements. Accessories are fabricated from premium materials to assure durability and virtually no maintenance, reducing or eliminating costly service interruptions for the life of the tank structure. Like the tanks themselves, accessories are designed to comply with all applicable local, state, and federal regulations. Accessories include:

Construction

The Leading Design Built By Preload's Leaders in Construction

A design is only as good as the construction professionals who build it, their construction processes, quality control focus, and safety commitment. Preload trains and equips all of our valued construction employees with the knowledge and tools necessary to be successful professionally and personally. Each of Preload’s tank construction processes has been developed and refined over decades and thousands of tanks. Consistently implementing these proven processes, verified with a thorough quality control program, assures generations of durable and reliable tank service.

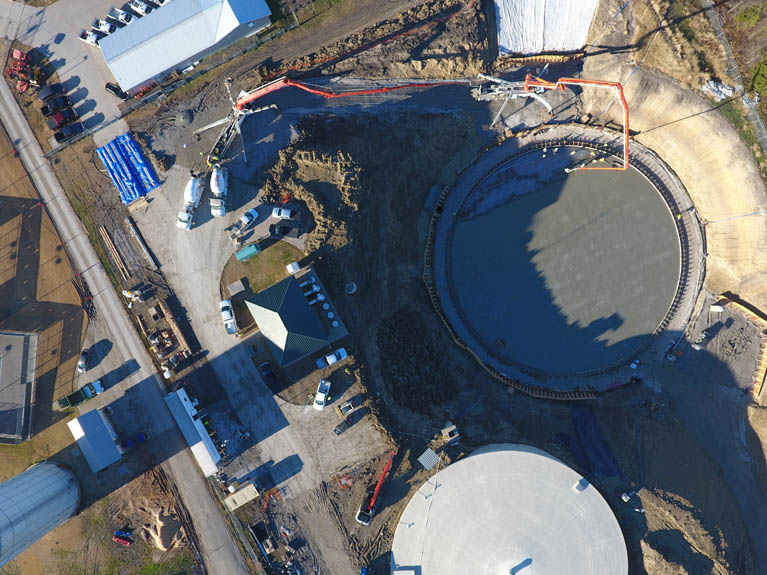

FOUNDATION

PRELOAD TANKS START WITH A SOLID FOUNDATION

Tank construction begins with the foundation. A solid tank foundation requires thorough subbase preparation. Our engineers carefully review each project to ensure that geotechnical issues are correctly addressed throughout the subgrade and subbase preparation.

After the sub base is prepared, a minimum 6” thick leveling course of granular material is placed on top of the subgrade. This allows for a free-draining work area to facilitate construction and ensures close tolerances in constructing the finished floor.

The Preload Team’s expertise and experience in tank foundation design and construction are unequaled in the industry.

Shallow Foundation

The most common tank foundation is a Shallow Foundation, where the tank floor and footing loads bearing directly on native soil or engineered fill. The foundation soils are usually prepared by excavating unsuitable soils, proof rolling/inspecting the subgrade, and replacing the unsuitable soils with controlled, compacted structural. A shallow foundation is typically used in conjunction with a concrete membrane tank floor. However, certain scenarios such as very high tank structural loads or unsuitable soils extending below a practical depth may deter the use of a conventional shallow foundation. In this case, foundation options include a deep (pile) foundation or a ground improvement foundation system.

Deep Foundation

Deep foundation systems support tank structural and liquid loads through the use of a structural element (steel H-pile, auger cast-in-place pile, precast concrete pile, drilled shaft, etc.) installed to a soil bearing layer or a sufficient depth to provide end bearing support, adequate skin friction over the pile length for support or both. The piles support the compressive load and other loads from the structure with minimal deflection vertically. Usually, the vertical deflection of a pile is considered minimal. As the tank floor bears directly on the piles, a structural concrete tank floor is used to resist shear from the pile points loads and bending moments between piles.

Piping

PIPING FOR WATERTIGHT TRANSMISSION

Uninterrupted liquid transmission to and from the tank is vital to the operation of the storage facility. The Preload Team uses time-tested design and construction details that ensure

- Proper installation of the piping to exacting tolerances,

- Exceptional concrete encasement of underground and internal pipes, and

- The flexibility required to allow differential settlement or movement of the pipeline relative to the structure.

Our detailing and installation of the tank piping results in high quality and watertight service.

FLOOR & FOOTING

WATERTIGHT LIQUID CONTAINMENT

Preload constructs a highly reinforced concrete membrane floor that transfers the liquid load directly to the subgrade and contains the liquid in the tank. In conjunction with a custom-designed PVC water stop, this type of floor system provides water tightness and the ability of the floor to settle differentially without being subjected to high secondary bending stresses. The result is a reliable, economical, and durable tank structure.

Where site conditions necessitate using a structural floor, we choose design details and construction compatible with the pile supports, rock anchors, or other deep foundation systems.

In either case, our construction methods call for the installation of reinforcing steel and consolidation of properly prepared and tested concrete mixes that render high-quality, watertight tank structures.

RESTRAINT

BUILT TO WITHSTAND THE FORCES OF NATURE

In high-seismic areas or sites with uneven backfill elevations, restraint cables are utilized to minimize lateral displacement of the cylindrical wall relative to the tank footing.

Preload pioneered the use of restraint cables in prestressed concrete tank structures. Our restraint system is proven to assure superior tank performance in any situation.

WALL

PRELOAD – THE ORIGINAL INVENTOR OF WIRE-WOUND PRESTRESSED CONCRETE TANK WALLS

PRELOAD engineered the first wire-wound prestressed concrete tank wall more than 70 years ago and has been at the forefront of continuous industry innovation ever since. Today’s industry standards for specifying and constructing prestressed concrete tanks are largely due to the technology, methods, and practices PRELOAD brought to the industry. These include industry-accepted publications AWWA D110 and ACI 372R, used to guide the design and construction of prestressed concrete tanks throughout many parts of the world.

Whether it is an AWWA D110 Type I, Type II, or Type III tank, PRELOAD has the experience and capacity to construct your storage structure.

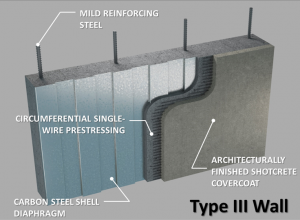

Wall - Type III

Type III Tank Walls – The Superior Choice in Prestressed Concrete Tanks

The Type III tank wall represents an innovation in prestressed concrete tank design and construction methods. PRELOAD’s Type III tanks provide maximum quality control during construction and more excellent durability. Our advanced techniques for precasting wall panels and unequaled quality control make a Type III design the best option.

Type III tank wall panels are precast by the PRELOAD Team on-site and shaped to the proper curvature of the tank radius. Panels are constructed in casting beds and then stack-cast in an efficient assembly line process.

A steel diaphragm is used as the bottom form in fabricating each panel. The steel diaphragm is vertically ribbed with reentrant channels, providing a mechanical keyway anchorage to the concrete. The individual diaphragm sheets are mechanically lock-seamed. This process, invented by PRELOAD, produces an impervious watertight membrane throughout the entire wall area.

Next, side forms are positioned to form the edges of the panels, vertical reinforcing and lifting inserts are placed, and the concrete is cast and finished. As the concrete is cast, the thickness and cover over the diaphragm and reinforcing steel are positively controlled by the side form system. This process ensures a minimum of 4” of densely consolidated concrete cover over the steel diaphragm and proper cover over the reinforcing steel. Each panel is then cured in a high-humidity environment.

Once all wall panels are cast, the individual panels are rotated vertically and erected along the perimeter tank footing. The panels are then temporarily braced as the wall construction continues, ensuring safe construction in nearly any weather condition. The diaphragm is then joined together, and joints between the erected panels are filled with shotcrete or concrete. Once the wall construction is complete, the circumferential single wire prestressing is applied.

If required, PRELOAD can embed inserts to support internal tank accessories. Wall sleeve penetrations that accommodate permanent manholes and through-the-wall piping are made watertight by sealing them to the steel diaphragm.

Wall - Type II

Type II Tank Walls that Exceed Industry Requirements

The construction methods used for Type II tank walls were developed by PRELOAD in the 1940s. While the basic methods remain largely unchanged today, advancements in materials and construction techniques have allowed PRELOAD to improve the tank’s quality characteristics.

A galvanized steel diaphragm with vertically ribbed reentrant channels is at the core of each PRELOAD Type II tank wall, providing a mechanical keyway anchorage to the shotcrete. The steel diaphragm is seamed and sealed to form a watertight, impervious barrier from the base to the top of the tank. Mild reinforcing steel is then placed in the wall to resist stresses due to differential temperature gradients and vertical bending moments.

Permanent manholes and through-the-wall piping, if required, are accommodated through penetrations made watertight by sealing them to the steel diaphragm.

Finally, shotcrete is pneumatically applied to the interior and exterior of the steel shell diaphragm to build out the tank core wall. This process allows efficient construction of the tank wall and is performed by one of our specially trained, ACI Certified Shotcrete Nozzelmen.

If required, PRELOAD can attach internal tank accessories to the tank wall using embedded or post-installed anchors.

ROOF

NO MATTER THE PROJECT REQUIREMENTS, THE PRELOAD TEAM HAS YOU COVERED

The Preload Team’s expertise allows us to assist with selecting and constructing the right cover for your storage tank.

As a leader in dome-roof construction, our time-tested construction methods enable us to construct a high-quality dome for your tank for maximum long-term durability.

For projects with height restrictions or fully buried tanks, we utilize a column-supported flat-slab concrete roof.

On projects where a roof isn’t required, our open-top tanks are a perfect choice.

Dome Roof

Most Preload tanks feature a spherical shell dome roof

The dome roof design is unmatched in its economy and durability. The design results in uniform compression throughout the spherical shell, allowing relatively thin concrete sections to span large tank diameters.

The efficient dome shape provides a low profile as well. Rise-to-diameter ratios of 1:8 to 1:12 are standard, depending on tank diameter. Other rise-to-span ratios are available on request.

In constructing the roof, reinforcing steel is placed in perpendicular directions throughout the dome shell. Then, the concrete is placed onto the form, finely screeded, and finished to the required spherical shape. A thickened fillet section is incorporated at the dome perimeter to resist the bending moments resulting from shell edge discontinuity.

Preload’s dome designs include venting for the adequate draft and an access hatch for future entrance or the use of equipment.

Flat-slab Column-Supported Roof

Reinforced concrete, flat-slab roofs for prestressed concrete tanks with special form or aesthetic requirements

At times a flat-slab column-supported roof is required for fully buried tanks, for a project’s height restrictions or for aesthetic reasons. Preload’s flat-slab roof is supported by circular columns, each with a footing sized for the allowable soil-bearing capacity. To economize the design, we use column capitals or drop panels compatible with the roof design.

Our flat-slab roofs are designed and constructed to meet local and project requirements. They are designed per the AWWA D110 Standard, ACI 372R, and the ACI 350 Code for Environmental Structures.

Open Top

When a roof isn’t a requirement

For certain applications, Preload’s prestressed concrete tanks are constructed with an open top. Like our dome or flat-roof tanks, Preload’s open-top tanks consist of

- A circular, cast-in-place, reinforced, concrete floor slab

- A precast, circumferentially prestressed, concrete wall incorporating a continuous mechanically bonded steel diaphragm.

Preload’s open-top tanks are constructed to meet the requirements of the AWWA D110 Standard, ACI 372R, and our own high standards for tank construction.

Our quality-centric construction methods result in an open-top tank with tolerances that will incorporate any process equipment necessary for your project.

PRESTRESSING

CIRCULAR PRESTRESSING IS OUR BUSINESS

Circular, single-wire prestressing is the time-proven method Preload invented for constructing wire-wound prestressed concrete tanks. Prestressing places the entire tank wall into a state of permanent compression. This prevents the cracking and leaking associated with other types of tank structures. Prestressing the dome edge keeps the dome in compression, enabling the use of large free-spanning concrete domes.

The prestressing wire is applied around the tank in a continuous helix, using specially designed machines capable of exceeding industry standards and meeting our own stringent quality requirements. These machines allow us to maintain a consistent force in the wire while maintaining a minimum clear distance between individual prestressing wires to ensure that every wire is fully encapsulated in shotcrete.

Encapsulating individual wires and applying them helically eliminates the need for buttresses and anchorage zones. This benefit is found only in wire-wound prestressed tanks, resulting in superior reliability and durability.

COVER COAT

QUALITY AND BEAUTY THROUGH THE FINAL STEP

The final step in the construction of the tank structure is the exterior cover coat. Concrete is applied pneumatically in a process called shotcreting. The concrete is applied or “shot” onto the wall with air pressure, typically in layers.

Our skilled ACI-certified shotcrete nozzlemen apply the cover coat, thus ensuring high-quality construction in the finished tank structure.

The final surface of the cover coat is architecturally finished by applying either a natural gun or a steel-troweled finish to produce a durable and aesthetically-pleasing tank structure for the community.

Architectural Treatments

WHEN IT COMES TO WATER STORAGE TANK DESIGN, DIFFERENT COMMUNITIES HAVE DIFFERENT AESTHETIC NEEDS

That’s why we offer a wide range of design possibilities, enabling you to choose the look that best suits your environment. We build Preload tanks in diverse configurations — including at grade, partially buried, or fully buried — to satisfy your profile preferences and accommodate specific site conditions.

Additionally, with a Preload tank, you can select from a wide range of colors and geometric alternatives, as well as exterior treatments to blend with nearby structures and the surrounding environment. Whatever your location, we’ll build the right tank to suit your community’s needs.

PILASTERS

Pilasters provide a simple yet striking aesthetic feature to your tank. Pilasters can be made from precast panels, shotcrete, brick, and EIFS.

ROOF PERIMETER PANELS

Concrete Panels or concrete parapet and ring the tank edge to visually extend the wall above the roof. This technique is typically used when masking the concrete dome is desired for low profile tanks and/or partially buried tanks.

ARCHED PILASTERS

Arched Pilasters are similar to pilasters with the addition of an arch between pilasters. Arches are often seen as a complement to the visually appealing dome. The arches and pilasters can be painted in contrasting colors to the rest of the tank creating a distinctive visual appeal.

BRICK FACING

Brick facing is similarly installed on tanks to brick facing for buildings. The brick is non-structural and supported by a brick ledge integral with the wall/footing. Brick is commonly utilized to blend the tank in with other similarly brick-faced structures such as pump stations or treatment buildings.

EXTERIOR INSULATION & FINISHING SYSTEM

Commonly known as EIFS, this architectural system provides the greatest flexibility of design and color. We can construct detailed shapes and textures to disguise the tank as a building, monument, or intricate pattern.

EXTERNAL CLADDING

External Cladding is installed to mask the specific aesthetic features of the tank. This cladding effect can be created from various materials, including panelized insulation for tanks requiring internal liquid temperature control. Cladding can also be combined with canopies and lighting to create depth and illumination.